Here you can find some inspirational examples of successful ecodesign!

Have a look at these forward-looking ecodesign cases we want to share with you!

The new single grain seeder enables corn kernels to be sown on the field with pinpoint accuracy and fertilizer pellets to be deposited precisely below the respective corn kernel. This makes it possible for the first time to fertilize in line with requirements, thus conserving resources and protecting the environment.

This suction and irrigation system is very resource-efficient and can be used up to 150 times in operations. Conventional systems have to disposed of after one use.

Due to the ecodesign of bottles and bottle boxes Dr. Gab´s yields lighter bottles, less transport and glue-free cardboard. Impact savings for the project were in the order of 215 tonnes CO2 eq per year.

WZR ceramic solutions GmbH devised a light, steady and highly-efficient ceramic kiln-furniture. Its paper-base has a high ceramic amount and becomes a solid fireproofed material after heating it up. The corrugated paper structure saves time, energy and space while burning ceramic products.

This drawer-system is a premium-quality product with a long lifespan which can be assembled in only one minute. Its height, width, depth and colour is chooseable and thus individual. TA’OR BOX maximises the available storage space and uses up to 96% less wood.

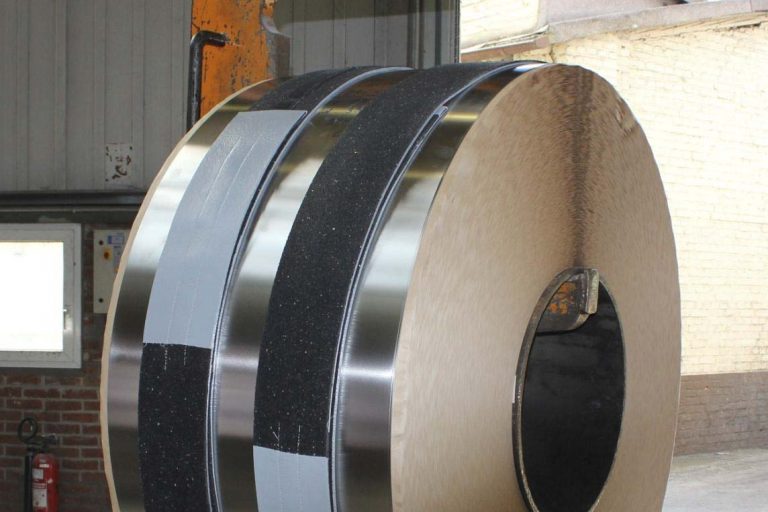

This is Ecodesign because it uses nearly 100% recycled material (scarp tires) and can be re-used several times. The optional products are only used one time. It protects the coil and reduces the steel scrap through damages during transportation. Nearly 100% can be recycled and is applied to the coil in have the time of conventional protection systems

Regupol uses recycled polymer raw materials to manufacture anti-slip mats, sports flooring, products for impact sound insulation and protective and separating layers for flat roofs. The recycled content of the raw materials used for this purpose is between 75 and 95 percent.

The mattress and topper are developed according to the Cradle-to-Cradle principle (regeneration or second life possible) and are part of a largely circular innovation process without staples, glue or PU foam’ is the key.

The HNST collection contains 56% recycled denim and uses removable and replaceable buttons. It has embroidered rivets instead of metal ones and is made with the cleanest indigo dyeing and washing techniques.

Besides it offers a probiotics spray for naturally cleaning and is transparant in it’s price setting and production partners.

XANT M is a midsize turbine and easy to install, easy to transport and more adaptable to the landscape than other wind turbines. It uses recycled tarpaulins of trailers of the client’s truck as cover and the swept-back shape allows maximizing the efficiency while minimizing material usage.

EMMA Safety Footwear crafts high-quality safety shoes for every sector. Sustainability is in their DNA. Therefore it is a logical step for EMMA to reduce the environmental footprint of their shoes. Safety and comfort are paramount in the design of safety shoes, but durability and low environmental impact are just as important.

The Ecodesign by OVAM Award 2022 goes to OpenStructures. This company translate the complexity of ecodesign into a kind of collective system that offers infinite possibilities.

OpenStructures developed one grid that they share as an open concept with everyone and with which companies can get to work.

This alternative coating to spray-type zinc phosphating prevents phosphate sludge emergence, waste water doesn´t arise and due to the discontinuation of pollution abatement facility the energy demand and the carbon dioxide emissions can be reduced enormously. The new coating for cold-forming is priced by the Effizienzagentur NRW in 2015.

With the help of a modular CO2-calculator Kleeschulte Erden minimizes the greenhouse gas emissions in the production of climate-friendly earths- and substrate composites. The analytic engine simulates the expectable emissions and reveal the existing saving potentials. Owing to this machine the company decreased the emissions of their products net of 2.074 t CO2eq per year.

The case for the single-board computer Raspberry Pi out of cardboard called “pius” satisfies the user’s needs and is furthermore sustainable. It is very light but also strong. Due to the glueless folding technique the transport is cheap and efficient. This ecodesign case is made by Jonathan Pohlke and is priced by the MehrwertNRW Price.

Each year, 15m kg-worth of headphones are thrown away. They have slight defects or have been replaced by a more recent model. A load of materials are thus lost, which is not really necessary. This inspired Gerrard Street to market a pair of modular headphones. What makes Gerrard Street’s headphone design unique is that they are not for sale; rather, they can be leased.

Discover more cases on OVAM´s website

and cases in Flanders!